removing the coupling, gear,or pulley (sheave) from an electric motor shaft

Electric motors are used to run machinery, pumps, compressors, blower fans, and all other kinds of equipment. Without motors, none of these machines will move.

The shafts of the electric motors are coupled to these machines using some kind of attachment. It could be a sheave (pulley), a coupling, or a mounted gear.

When electric motors are up for repair, it has to be disassembled and parts that are defective need to be repaired.

The end bell also called the end shield or end cap of the motor cannot be removed and bearing housing inspected if there is something attached to the shaft.

This post includes:

Steps on how to remove gear from electric motor shaft

Steps on how to remove a sheave (pulley) from an electric motor shaft

Tips on how to remove a coupling from an electric motor shaft

Tools you need to remove gear, coupling, and sheave (pulley). What to do if you don’t have them.

7 Steps on how to remove gear from The electric motor shaft

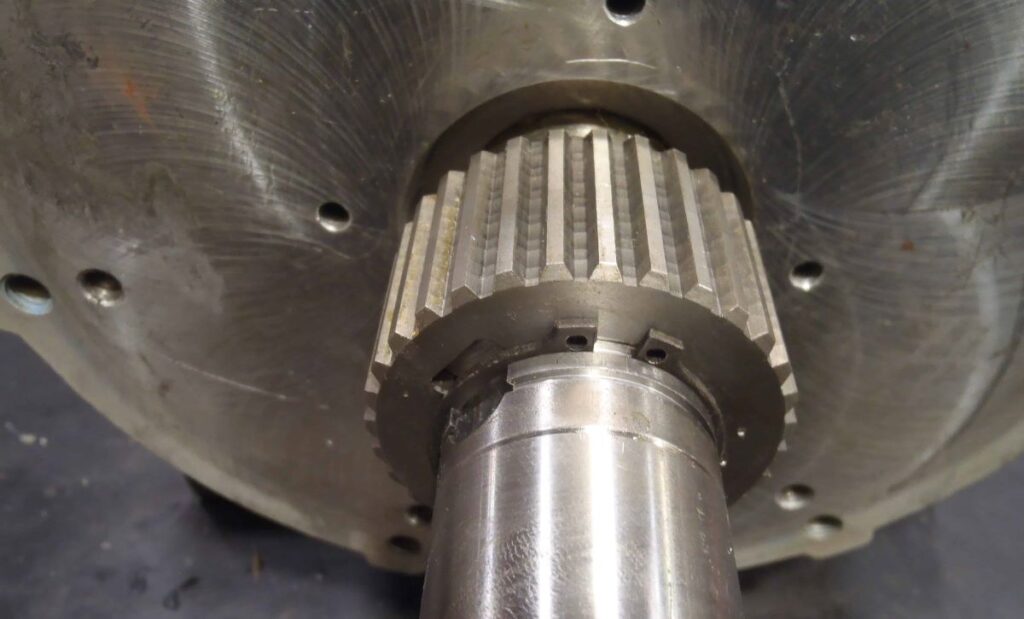

Electric motor shafts with helical gears are used on conveyor motors, roller motors, and gearbox motors while spur gears are commonly used on the motor as a spline for its brake or clutch.

Here are the steps:

- Before removing gear from the motor shaft, measure the distance of the gear to the end of the shaft. This is so that you can reinstall it back at the same position later. Not unless it rests on a shoulder and/or a snap ring.

- Check and remove anything that holds the gear to the shaft like a set screw or a snap ring. Sometimes a snap ring covered with grease is hard to see.

3. To remove gear from the shaft, use a two-jaw or a three-jaw puller.

4. When a gear is tight that the jaw keeps on disengaging, use a chain grip. This will keep the puller engaged.

5. Another way is to use a bearing separator and a bar-type puller. Position the bearing separator behind the gear, screw in the threaded rods of the puller, and remove the gear.

- To remove a gear without a puller, use the rosebud tip of an oxyacetylene torch and heat the gear. As soon as it is hot, lightly tap it out.

Use leather gloves and a face shield when using oxyacetylene

- You can also use an arbor press if you are working on a small motor and the diameter of the end bell will fit the press. Put a bearing separator behind the gear and press the gear out using the press.

Removing a sheave (pulley) from the electric motor shaft

Some machines are coupled to the motor using v-belts and at times flat belts.

Sheave (pulley) is installed to the shaft either directly or through a hub or bushing.

Electric motor sheave pulley with a bushing Is a two-part assembly. Pulley is first unbolted and removed from the bushing then the bushing is removed from the shaft.

Some pulleys have no bushing. It is only held to the shaft by a key and two set screws

This is how to remove pulley or sheave from the electric motor shaft:

1. Before removing the sheave pulley from the motor shaft, measure its distance to the end of the shaft. This is so that you can reinstall it back at the same position later

2. If it is held by a bushing, measure the face of the bushing to the end of the shaft.

3. Check for set screws and remove them.

4. Pulley is usually bolted onto the bushing using four bolts. It also has two threaded holes to accommodate the jacking bolts for easy removal of the pulley. Remove the bolts.

5. Spray the pulley, the bushing, and the shaft with an oil lubricant.

6. If the shaft is rusty, use an emery cloth or sandpaper to remove and clean the shaft.

7. Get two from the bolts that you have removed, and install them on the two threaded holes on the sheave pulley. If the bolts are short, replace them with longer ones. Use this as jacking bolts

8. Tighten these two bolts to remove the pulley. The bushing is tapered, so the pulley should just pop out.

9. The bushing has a sliding fit to the shaft but because of corrosion and the key, it could be tight. One way of removing it is by the puller.

10. Another way of removing it is by jamming a screwdriver on the split of the bushing. This will allow for the bushing to increase its diameter for easy removal from the shaft. For pulleys that do not have bushing, use either a two-jaw or three-jaw puller to remove it.

11. Do not grab it by the pulley groove or you will break it. Some pulleys have bolt holes to accommodate the puller.

12. For pulleys that don’t have bushing, you can also use a bearing splitter and position it behind the pulley. Put the puller jaw behind the splitter to remove the pulley.

13. If that doesn’t work, use heat. Heat the pulley using the rosebud tip of oxyacetylene and soon as the pulley is hot, it should just slide out of the shaft. Be cautious, it’s hot.

5 tips on how to remove a coupling from an electric motor shaft

1. Before removing the coupling from the motor shaft, measure its distance to the end of the shaft. This is so that you can reinstall it back at the same position later. The coupling could be flush to the end of the shaft, out, or in by a certain distance. Make sure you take note of the position or have a picture.

2. Check for set screws and remove them

3. Use a puller to remove the coupling.

4. Most couplings are a tight fit. If you’re having a hard time with the puller, combine it with heat. While the puller is engaged, heat the coupling using the rosebud tip of the oxyacetylene and soon as the temperature reaches about 300C, continue pulling it out with the puller

.

removing the coupling, gear,or pulley (sheave) from an electric motor shaft Read More »